The production of FCB multilayer board is not simple to follow the process to complete the board, drilling a hole to hit the components. The manufacture of PCB multilayer circuit board is not difficult, but the difficulty lies in the troubleshooting after the completion of the production. Whether personal enthusiasts or industry engineers, it is also a headache for PCB circuit boards to encounter problems during debugging, just like programmers encounter BUG.

Some people have a strong interest in debugging PCB circuit boards, just like programmers are solving BUG--like, there are many common PCB circuit board problems, in addition to circuit board design, damage to electronic components, circuit short circuit, the quality of components, PCB circuit board break fault is not a few.

CommonPCB circuit boardThe fault is mainly concentrated in the components. Above, such as capacitors, resistors, inductors, diodes, transistors, field effect transistors, etc., the obvious damage of integrated chips and crystal oscillator, and the more intuitive way to judge the faults of these components can be observed through the eyes. There are obvious cauterization marks on the surface of obviously damaged electronic components. Faults like this can be solved by simply replacing the faulty components with new ones.

Of course, not all damage to electronic components can be observed with the naked eye, such as resistors, capacitors and transistors mentioned above. In some cases, the damage can not be seen from the surface and requires professional inspection. I tools for maintenance, commonly used for inspection are: multimeter, capacitance meter, etc., when it is detected that the voltage or current of an electronic component is not in the normal range, it indicates that there is a problem with the component or the previous one-component. Directly replace it and check again to see if it is normal.

If the components are broken, they can be detected either with the eyes or with the instrument, but sometimes when we put the components on the PCB board, we will encounter the situation that there is no problem with the detection, but the circuit board cannot work properly. Many beginners have no choice but to make a new board or buy a new one. In fact, when we encounter this situation, most of the time, the performance of the components may be unstable because of the coordinated work of the various components in the installation process.

In this situation, the instrument can no longer help, you can try to judge the possible scope of the fault according to the current and voltage, and minimize it as much as possible. Experienced engineers may be able to quickly judge the fault area, but the specific components which are broken can not be 100% sure. The only way is to try to replace the suspicious component until the faulty component is found. Last year, there was water on my notebook motherboard. I also encountered that the fault could not be detected when I was repairing the master, and I replaced the components three times during the maintenance process, namely, the power supply chip, the diode, and the USB charging element (the blue socket of the notebook, which can charge the device when off). Finally, I also replaced the suspicious chip through one-wave detection and troubleshooting. It was finally determined to be a short circuit of a component on the edge of the Nanqiao chip.

In fact, the above is the problem of electronic components, of course, since the PCB circuit board as the foothold of components, then the circuit board fault must also exist, the simplest example is the dead tin plating part, due to the production process, in the PCB corrosion process, there may be wire breaking problem. In this case, if it is impossible to make up the wire, it can only be solved with fine copper wire.

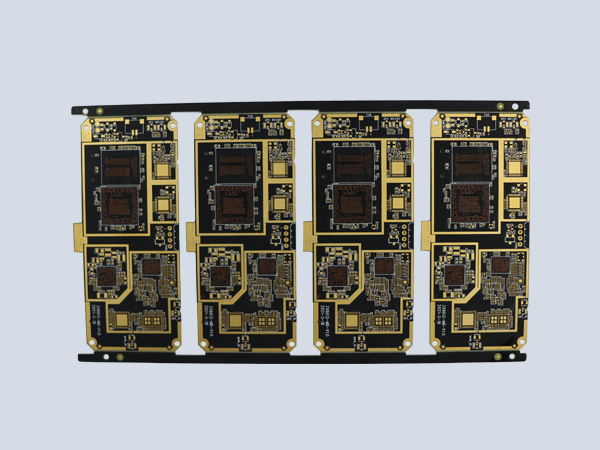

PCB circuit board fault is not obviously damaged in the case, check is indeed very troublesome, and in the troubleshooting process, there will be a spirit of focus, to find out the problem after there will be an inexplicable sense of achievement, programmers to solve BUG is this kind of mood, I often like to check some difficult to repair the board, this is probably the happiness of HDI multi-layer board engineers.